Mounting A Washer-Extractor

There are two types of washer-extractor mounting systems: suspended or soft mount and rigid or hard mount. They both have their own advantages and disadvantages, and should be carefully considered when choosing a machine mounting design for a laundry wash aisle.

Suspension systems on washer-extractors are designed to absorb machine vibration without the need for special foundations. The system adds parts and components to the machine but reduces the site foundation requirements. Suspended washer-extractors typically have a larger footprint than a comparable rigid mount due to these extra parts and components. Suspended machines range from smaller 60-pound models up to 450-pound capacity and beyond.

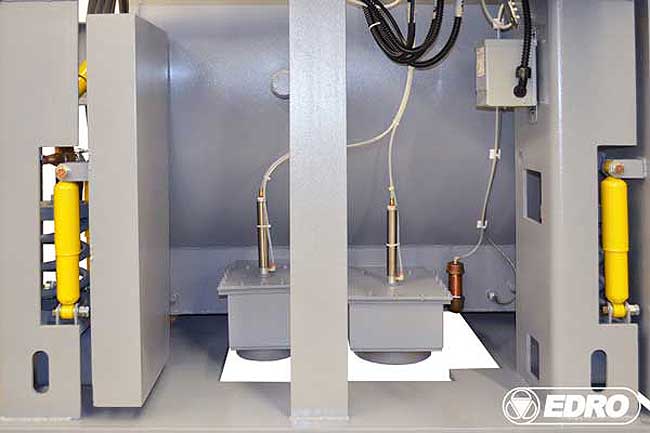

The EDRO DynaMount suspension system is made up of independent spring assemblies that incorporate heavy-duty, reverse-loaded coil springs and a set of permanently sealed, tuned shock absorbers. Additional shock absorbers are mounted to the washer-extractor's frame for further stabilization.

Rigid mount washer-extractors, particularly multi-pocket machines or machines with a center down drain already require a trough to drain to and, therefore, the foundation associated with this wash aisle setup can already accommodate the additional requirements of a deeper footing.

Either mounting method has to deal with the out-of-balanced extract steps that cause vibration. Out-of-balance steps are normally caused by under loading the washer-extractor or lumping of the load in between ribs or pockets. Suspended machines are somewhat better capable of handling these occurrences because of the vibration sensing technologies of limit switches and sensors.

However, inverter drive monitoring and EDRO's exclusive variable step extract sequencing result in smoother speed transitions between washer agitate, distribution and acceleration to final high extract speed. The unique speed algorithm of the variable step extract spins the machine faster and faster as more water is removed from the load. This results in less and less water weight in the load as the machine spins faster and faster.

As speed control and vibration sensing technologies have improved, the rigid mount capacity threshold has grown. Machines are now offered upwards of 200-pounds in the open pocket design and 400-pounds in the split pocket design.