Water Extraction and Moisture Retention

The extract function reduces moisture retention in the laundering process. The process begins with textile saturation. Free water will not accumulate in the cylinder until the textiles have absorbed enough water to become saturated.

Saturation Examples:

Cotton

- Approximately 0.3 gallons per pound (lb) of cotton or 2.5 lb of water per pound 100%

Polyester

- Approximately 0.1 gallon per pound (lb) of polyester or 0.8 lb of water per pound

Therefore, a 350 lb load of cotton will hold approximately 105 gallons (876 lb) of water when saturated and a 350 lb load of 100% polyester will hold approximately 35 gallons (280 lb).

The amount of water needed for saturation must be added to the amount of free water in the washing cylinders when the water consumption of laundering formulas is calculated. The extract function reduces the water content of textiles to 25% to 70% moisture retention depending on the fabric laundered and equipment used.

Moisture retention describes the ratio of retained moisture weight to clean dry textile weight. Clean dry weight is normally calculated by using the weight after full drying to "bone dry state."

- One pound of cotton textile holds 2.5 lb of water (0.3 gallons) or 250% of the dry weight

- The extract function decreases retained moisture to a level of 50%, a removal of two pounds of water per pound of fabric

- Since 50/50 polyester/cotton retains only 1.7 lb of water per pound of fabric, only 1.2 lb would be removed to reach the same 50% moisture retention. However, polyester/cotton textiles come out drier for the same extraction effort

Extraction is performed in the washer-extractor; the pre-programmed PLC moves the washer into high-speed rotation after the laundering cycle.

With conventional washer-extractors, the load has to be removed from the washer and extracted separately. Extraction is carried out using either centrifugal or hydraulic extraction. With centrifugal extraction, the centrifugal force (G-Force) spins the water out of the fabric at high speed.

There are two types of hydraulic extraction. In the first, the water is squeezed from the fabrics by utilizing fluid pressure exerted against a flexible diaphragm that houses the textiles. In the second type of hydraulic extraction, the fabrics are placed between a piston and a bulkhead. The piston is forced towards the bulkhead, squeezing the water from the textiles.

In tunnel washing equipment, moisture is usually extracted with a hydraulic press, but centrifugal extraction is an efficient choice for certain classifications of textiles if batch cycle times allow.

There are advantages and disadvantages to each extraction method. Water removal using the extract function is more cost effective than dryers, ironers, presses, etc.

Extraction from textiles is enhanced by increasing water temperature and the incorporation of fiber lubricants (e.g., fabric softeners) in the sour bath. The warmer the fabric extracted, the better the moisture removal.

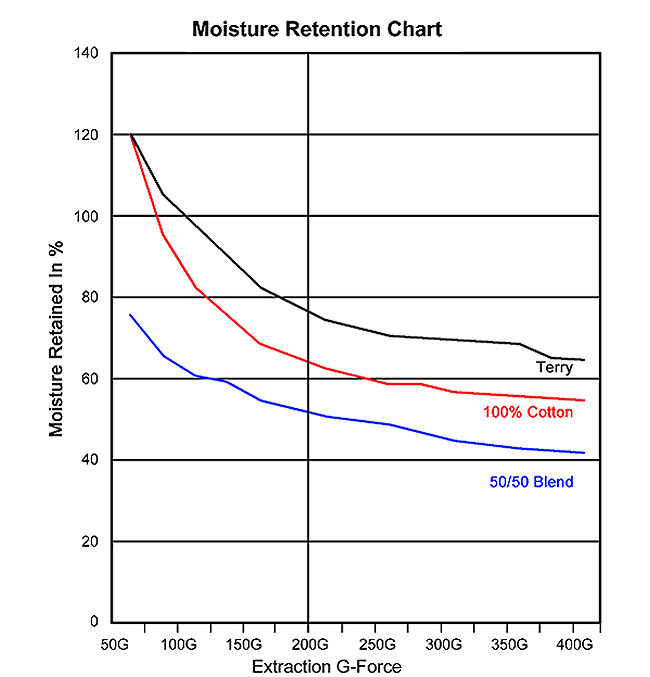

Shown below is a Moisture Retention Chart that demonstrates moisture retention in % when subjected to differing extraction G-Forces. Note that once G-Force exceeds 200G there is a diminishing return on the moisture removed from textiles compared to moisture removal from 50G to 200G.