Controlling Factors Of The Washing Process

To achieve the best possible laundering results, four controlling factors play an essential role in processing:

- Mechanical Action

- Chemistry

- Temperature

- Time

Variance in any of the above factors impacts the effectiveness of the laundering process.

Mechanical Action

Mechanical action is the movement of textiles within the washing cylinder and the flow of washing solution through them. Without mechanical action, detergency - the removal of foreign substances (soil) from textiles - is not effective. The rules that dictate mechanical action are based on cylinder and rib design and speed of the wash step.

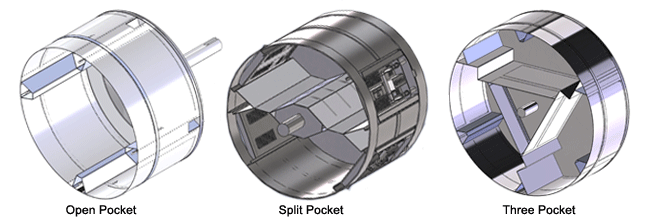

Three types of pocket design are utilized in washer-extractor design. They are open pocket, split pocket and three pocket.

Soil cannot be removed from textiles until mechanical action and washing solution are applied, regardless of time, temperature and the composition and concentration of chemistry utilized. Therefore, cycle time length, proper load size, wash speed and water levels principally control variations in mechanical action.

Chemistry

Another factor is the composition and concentration of chemicals employed in the laundry process. The concentration of chemistry plays an essential role in soil-and-water interface penetration, thus allowing mechanical action to free the loosened particles. The imprecise application of chemicals can lead to damaged fabrics or result in the discoloration of textiles such as graying, yellowing, etc.

Types of Chemicals

Detergents

In chemical terms, detergents are a subclass of chemical compound known as surface-active agents or surfactants. Detergent is often used, incorrectly, to describe a manufactured product that contains a surfactant and perhaps other additives to assist the cleaning process.

While some soils cannot be removed from fiber surfaces with mechanical action and water alone, most cannot. This is where surfactants play a role. The soil removal process involves loosening and lifting soils from the surface of a fiber and holding them in suspension until the soils can be removed by dilution. The main function of a surfactant or surface-active agent is to suspend soil, although it also plays a key role in loosening soil.

Bleach

The primary function of bleaching agents is bleaching the natural substances in cotton and cellulose fibers that make the fabric "yellow" and to bleach spots missed during the laundering process. Bleaching agents also bleach textile colors and should be avoided when laundering colored textiles. Bleaching also impacts the fiber structure and can reduce a textile's lifetime.

Sours

The fundamental purpose of the souring operation is to neutralize residual alkalinity with a mild acid or acid salt. In textiles, residual alkalinity is caused by:- The alkalinity levels of tap water

- Carryover from alkalis and detergents

- Hydrolosis of soap

Residual alkalinity in textiles can cause yellowing of white fabrics, fading or dulling of colored fabrics, skin irritation and/or odors.

Another function of the souring operation is to lessen the aggregation of iron in textiles laundered in water that has been contaminated by rust. The souring operation may also assist in:

- The removal of some metallic stains

- The destruction of some species of bacteria

- The setting of some classes of dyes

- The maintenance of white color

Softeners

Fabric softeners are usually cationic surfactants that operate as fiber lubricants that yield a wide range of properties to treated textiles. These include improved feel or "hand", suppleness, reduced harshness and a reduction in levels of static electricity. Fabric softeners also lessen extraction and tumbling times, improve shake-out prior to ironing and promote ease of finishing.

Softeners are applied in the sour bath or in a separate operation after souring. The softener is easily absorbed by cotton from water and remains in the fabric until subsequent laundering.

Fabric softeners are available as paste, liquid and dry concentrates. They are also available as ready-to-use liquids (diluted with water or alcohol), or dry products (diluted with urea or salt).

Ozone

There are numerous benefits to be gained from using ozone in laundry operations. With the proper wash programs, ozone can save substantial money on operating efficiencies. Total cycle time, hot water usage, and overall water usage can be reduced and still produce quality results.

Ozone systems allow laundry to be sterilized, disinfected, bleached and deodorized using reduced water, chemicals and heat during the washing process. When ozone is injected into the wash water, it provides complete disinfection of the laundered garments, even at ambient water temperatures. Ozone aids in the breakdown and dissolving of oils in laundered textiles. Garment life is also extended thanks to the decrease in wear by the reduction of chlorine, hot water and wash cycles.

Temperature

The next factor to consider is temperature.

- Higher temperatures promote washing compound and soil particle action by reducing surface/interfacial tension and water viscosity

- Higher temperatures enhance the movement of chemicals involved in the laundering process, making the chemicals faster-acting and more efficient

Most chemical reactions in laundering double in reaction speed every 18°F (10°C) increase. However, some chemicals and chemical systems also have maximum operating temperatures. Operating outside a chemical product's recommended range can produce quality problems, textile damage and/or operator health concerns.

Time

Time can be regulated by adjusting the number of minutes that each wash step runs.

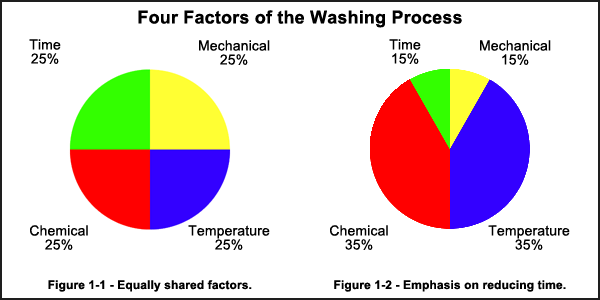

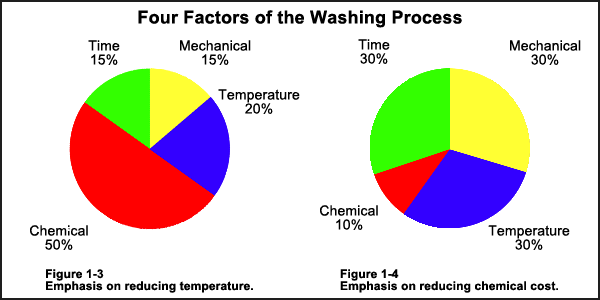

Mechanical action, chemicals, temperature and time all work together. Their roles can be inter-related in the form of a pie chart. The four factors share the total pie. If any one of the factors is reduced; one or more of the other factors must be increased in order to maintain the whole and produce desired results.

Excessive reduction of any one of the four individual factors can reduce detergency to a level that increasing another factor beyond its optimum range will not produce the expected improvement. For example, water temperatures close to freezing cannot be reasonably compensated for by the other three factors.

Source – Recognized Industry Documentation.