DynaCop Machine Networking

Introduced in 2012, EDRO DynaCop is built around a standalone Programmable Logic Controller (PLC) that supervises the extract process and timing of multiple EDRO washer-extractors.

Configured for the requirements of the site, DynaCop is designed to only allow a set number of washer/extractors to ramp up to EDRO's higher extract speed at the same time. For example, a site with seven washer/extractors may only want two in extract at the same time. So as the additional washer/extractors queue up for their extract step, the DynaCop maintains them in a holding pattern with EDRO's standard wash cadence until a release command is executed. At that point, the first washer in the queue begins its extract process.

EDRO's DynaTrol Touch Screen Control works in conjunction with the DynaCop. DynaTrol is designed with an out-of-balance safety. If an out of balance is detected during the extract step, the washer/extractor will come to a safe stop and then start the extract process for the beginning of the step to try and automatically correct itself. In this case, the DynaCop will move the out-of-balance washer/extractor to the end of the holding list.

DynaCop has been utilized on several sites to reduce the current draw along the power distribution branch during an extract step. It helps to reduce foundation vibrations by limiting the number of washer/extractors extracting at the same time. Since the DynaTrol logic incorporates draining as part of the extract step, the DynaCop also controls this draining process which has been useful for sites with less-than-desired draining capabilities.

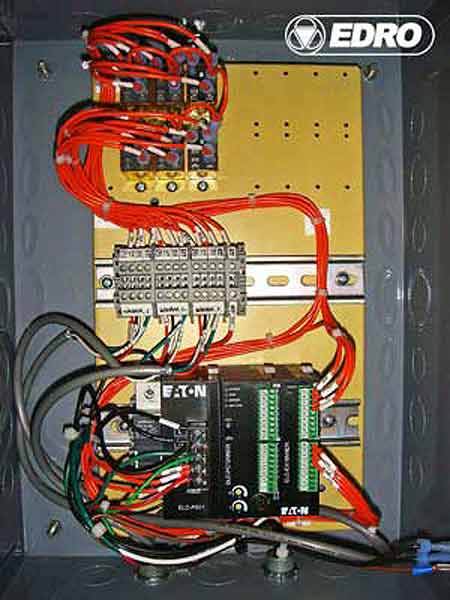

Typically mounted in the vicinity of all the washer/extractors, DynaCop is powered with single phase 110VAC-240VAC. Additional voltages can be provided with the addition of a transformer. DynaCop is then wired to each washer/extractor it is monitoring with a four conductor cable. DynaCop is field-upgradable via a handheld PLC transfer module that can be obtained directly from EDRO.