Exclusive Design of DynaWash® Washer-Extractors

EDRO's DynaWash® washer-extractor range is based upon its patented "3-D" wash basket design. The "D" describes the shape of each of the three compartments (pockets): a flat perforated floor for easy loading and unloading; top and bottom angled baffles for load separation and balancing stability; and a fully perforated outer basket wrap with lifting rib for superior mechanical action and maximum wash/water saturation.

Benefits of the inner design of the "3-D" stainless steel basket include:

- Dynamic wash action for superior cleaning results

- Maximum whiteness retention

- Minimal tensile strength loss

- Reduced tangling of goods

- Divided load in equal compartments

- Front and rear bearing support reduces cantilever vibration

- Drop level loading shelf

The unique basket construction also lowers the center of gravity of the machine, thus allowing for a more compact frame and base and significant reduction in vibration transmission. This means a stable washing platform and more washing capacity in less space.

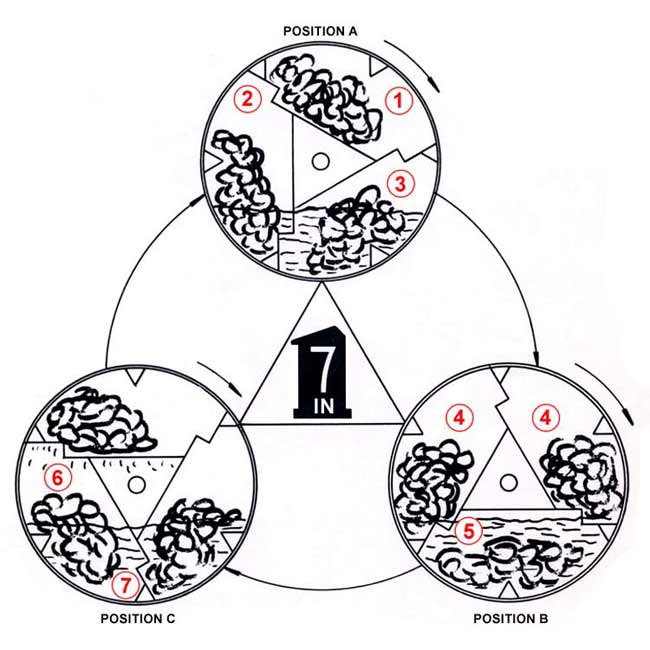

Seven Mechanical Wash Actions

The configuration of the cylinder compartments, and their pattern of perforation, is specifically designed to produce the seven mechanical actions that make for a good, clean wash:

POSITION A

- 1. Big Drop - load rotation begins by dropping from 11 o'clock to 3 o'clock

- 2. Secondary Drop - load rolls and continues to drop from 3 o'clock to 5 o'clock

- 3. Tumble - load tumbles as it is dropped into wash water

POSITION B

- 4. Double Squeeze - load is squeezed between top and bottom angled baffles

- 5. Float - load floats free to saturate in wash water

POSITION C

- 6. Force Push - load is forced through wash water

- 7. Draining - load gravity drains through fully perforated basket at top of rotation

These mechanical actions, combined with unrestricted circulation of the wash solution throughout the wash and rinse steps, afford the agitation, penetration and distribution required for quality results.

Over the years, EDRO has learned a lot about the design and performance of its three-pocket washer-extractors. After all, the company has built more than 5,000!

The machines industrial-strength construction has earned a reputation for being "Built Like a Battleship" and have been installed on plenty of them, including the Ford class, nuclear-powered aircraft carrier CVN-78 USS Gerald R. Ford and the San Antonio class, amphibious transport dock LPD-21 USS New York.

EDRO's customers have experienced the rugged design and quality construction that have resulted in years of tireless operation. It is not unusual to find the owner of a 30+-year-old DynaWash® machine looking to upgrade a replacement component when a competitive product would be replaced.

The company has listened to the people who use the DynaWash® washer-extractor range, and this feedback has resulted in product innovations such as:

- A barrier type PassThru for Clean Rooms configuration

- Energy-efficient inverter with single motor drive with variable step extract and high slip brake

- Exclusive DynOzone Disinfecting & Sanitizing Laundry System

This continual product improvement has fine-tuned the washer-extractor to provide solutions for laundry operations. Solutions that save valuable resources while producing clean laundry.

DynaWash® three pocket washer-extractors from the EDRO Corporation continually represent exceptional value in the laundry market. The low initial investment, below-average maintenance, remarkably low operating costs, robust design and solid construction have made the DynaWash® machine series a hallmark in the industry. DynaWash® washer-extractors feature top-quality parts and components and a machine design proven to be efficient and effective in laundry operations throughout the world.